In the lab of Professor Jennifer A. Lewis, sophisticated 3-D printers can deposit multiple materials in succession with extremely fine precision (photo 1). Madeline Cooper ’16 (left, photo 2) and Brian Boursiquot ’14 prepare hydrogel samples for a gel-based stent. Lewis (photo 3) challenged the students to learn “by having to actually confront something real and work their way through it.”

Image courtesy of Jennifer A. Lewis; photos (2, 3) by Lori K. Sanders

An introduction to rebuilding the body

Course on biomaterials puts undergrads on cutting edge

Just beyond the leading edge of biomedical research lie the medical tools of the future, where smart tattoos monitor changes in glucose levels, living tissues and organs are printed on demand, and implantable electrodes connect the nervous system to prosthetic limbs.

“It’s going to be a big deal, and I want to know all about it,” said Suraj Kannan ’14, a biomedical engineering concentrator who intends to pursue research in regenerative medicine and therapeutic tissue engineering.

Kannan was among 18 students who took “Introduction to Biomaterials” (BE 191) last spring. The new course at the Harvard School of Engineering and Applied Sciences (SEAS) is taught by Jennifer A. Lewis, the Hansjörg Wyss Professor of Biologically Inspired Engineering.

“Biomaterials is really the science of creating new materials for a biological purpose,” said Sarah Chapin ’16. “You need to know how these materials work, how you can create them, [and] how you can process them, in order to regrow any part of the human body or find something else to [replace a part] that was damaged.”

The course quickly brings students up to speed, preparing them to contribute to University research, pursue summer internships, or take an idea conceived in the classroom to the next stage of development.

“It’s a foundational course in biomedical engineering, whether you want to focus on medical devices, drug delivery, or tissue engineering,” Lewis said. “I want students to develop a toolbox based on understanding how materials and design influence the actual performance of whatever they’re making.”

By the end of the semester, undergraduates Alex Bartlett ’17 and Jessica Turner ’16 had come up with a new treatment for basilar artery stenosis (the narrowing of a major artery in the brain), and could explain why their gel-based stent would be safer and more effective than three leading treatments. Godwin Abiola ’14, Brian Boursiquot ’14, and Katrina Williamson ’14 proposed an implantable heart patch that could store and release medication on demand for patients suffering tachyarrhythmia.

“At other schools you wouldn’t necessarily have the opportunity to take something as detailed or in-depth on a particular area,” said Chapin, an engineering sciences concentrator in SEAS. “Here, that seems to be par for the course.”

The syllabus Lewis designed with Travis Busbee and Ryan Truby, two graduate teaching fellows from her research group, leads students through a conceptual hierarchy, from the materials’ atomic and molecular structure to their macro-level properties. While learning basic science in the context of biomedical applications, the students pick up concepts such as the differences between metals and polymers, the fluid dynamics of diffusion, the physics equations that describe stress and strain, and the importance of rational design.

Soft contact lenses, for example, are made of hydrogels. At the molecular level, these gels look like a mesh of interwoven strands that bond where they cross, with water filling the gaps. But hydrogels can be soft or stiff, stretchy or brittle, with large or small mesh, depending on the components used, the type of molecular bonds, and so on. An engineer who understands the chemical structure can manipulate it to target a particular function.

And those functions are a matter of lively research. Faculty labs at Harvard have recently developed hydrogels that can deliver chemotherapy drugs in response to an ultrasound trigger; stretch, like cartilage, without breaking; or assist in vitro studies of breast cancer. Materials scientists here have also created a transparent audio speaker made of hydrogel, demonstrating its potential for use as an ion-conducting artificial muscle.

Through hands-on lab exercises, students in BE 191 learned how to synthesize hydrogels, cure them with UV light, vary the composition to produce specific properties, and measure the gels’ rheological and mechanical behavior. Other in-class activities were designed to spur critical thinking and discussion.

“We had them do hands-on activities on the key topics before they were introduced in the lectures, to get them to think before they learned, by having to actually confront something real and work their way through it,” said Lewis.

“That was cool,” said Bartlett, “to see the actual physical fabrication side rather than just talk about, ‘This is what would happen.’”

Enhancing facilities for hands-on engineering education is a priority of the SEAS Capital Campaign. Additional instructional laboratories, modern design studios, flexible classrooms, and spaces for large, creative projects will be part of a new science, technology, and innovation community in Allston, of which SEAS will be the academic cornerstone.

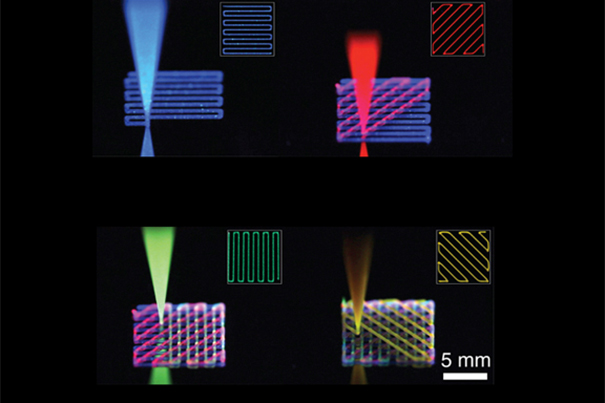

In the meantime, SEAS has invested in new equipment in its undergraduate teaching laboratories to support Lewis’ course: new desktop 3-D printers that can extrude soft materials, and new small-capacity load cells for measuring delicate hydrogels in a tensile testing machine. Lewis was recruited to Harvard last year with the help of a gift from Hansjörg Wyss. To start up her research program, SEAS provided a 4,500-square-foot laboratory, where her team uses — among other platforms — a unique 3-D printer that can pattern a wide range of functional materials with features smaller than 1 micron over large areas, all in a matter of minutes. Naturally, the syllabus for BE 191 included a unit on 3-D printing, an important biofabrication tool.

“It helps that Dr. Lewis is sort of the master in this field,” said Kannan.

Indeed, researchers in Lewis’ lab at SEAS and at the Wyss Institute for Biologically Inspired Engineering at Harvard, where she is also a core faculty member, recently 3-D-printed human tissue constructs that contained embedded vasculature and living cells; lithium-ion batteries the size of a grain of sand; and lightweight but strong carbon-fiber honeycombs. Students in BE 191 spent time in her lab and conducted two of their exploratory activities there.

“It was a chance for them to see a cutting-edge platform and see how materials can be essentially assembled with a multiscale approach, from designing the biomaterials used to construct them — the inks, if you will — all the way to printing complex 3-D architectures,” Lewis said.

If the lines are blurring between instructional and professional labs, Lewis said, it’s deliberate.

“I think it’s really important for students to walk into the ‘real’ labs and say, ‘Wow, this is the 3-D printer they’re using, versus my little desktop machine’ — to see that while some of the concepts translate, there’s a whole science behind it that goes beyond just, ‘I push a button and I get something,’” she said. “I think it’s essential for them to see that the things they’re learning in class are being translated in real time in faculty labs that they can join through an undergraduate research experience or a thesis project.” (In fact, Chapin will join the Lewis Lab this fall to carry out an independent research project on biofabrication.)

“The students who have taken Professor Lewis’ course now understand what it means to be a materials scientist, and what it takes to develop the next generation of materials for tissue engineering,” said Anas Chalah, executive director of active learning at SEAS. “I think the students get extraordinary benefit from the synergy between our active learning curricula and the world-class engineering research that’s ongoing in these labs.”

Bartlett, who enrolled in BE 191 as a freshman, was impressed: “When you do a lab in high school, it’s on a black desk that you also use for homework and eating and whatever else,” she said. “When you do labs here, you’re in a place where, really, innovation is happening — and you get to use it, too.”